Septic tanks are underground wastewater treatment systems that are commonly used in areas where there is no centralized sewer system. They have been around for centuries, with the first known septic tank dating back to 1860 in France. Septic tanks have evolved over time, with various designs and materials used to construct them. One of the most recent innovations in septic tank design is the plastic septic tank. Read More…

Roto Dynamics Inc., custom rotational molders serving rotomolding and plastic tank needs nationwide. We are dedicated to our customers manufacturing needs. Building customer relationships based on integrity and communication assists us in developing a competitive advantage within the industry.

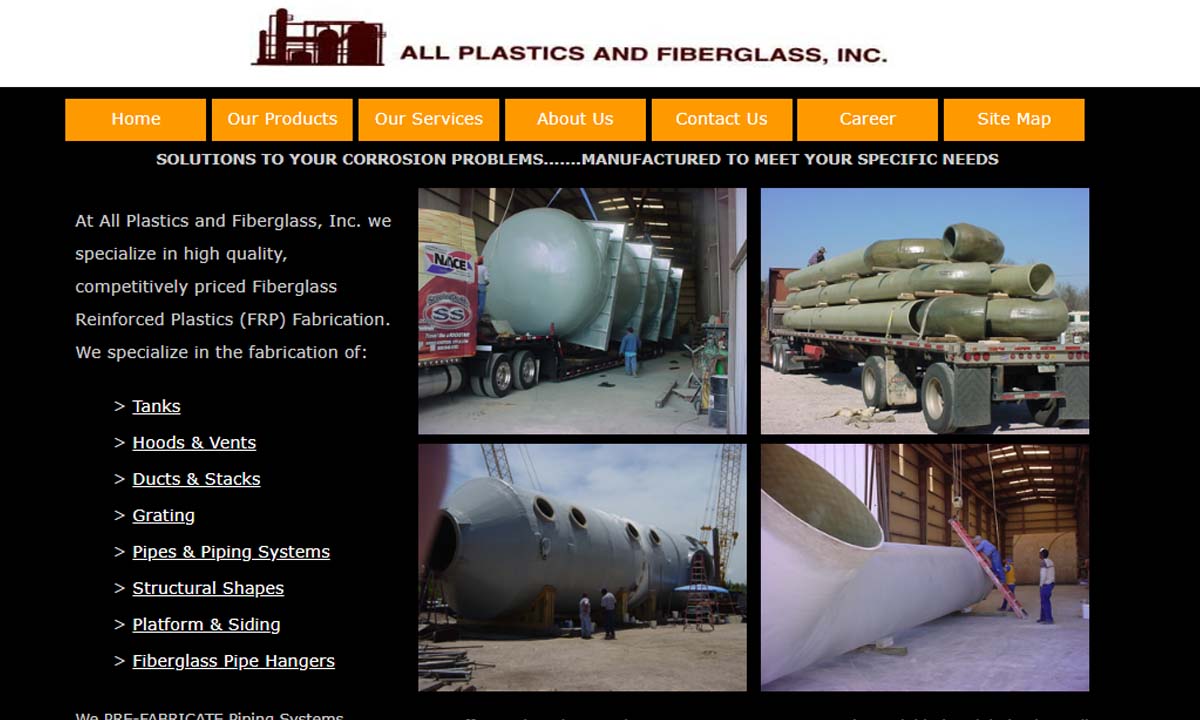

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your plastic and fiberglass needs.

Specializing in fabricated plastic tanks such as water tanks, polypropylene tanks, polyethylene tanks and storage tanks, Park Plastic Products is capable of making your plastic tank in any size or dimension.

Sherman Roto Tank specializes in tanks that are manufactured to be suitable to store and process chemicals. Our tanks are a great choice for any industry. All our products go through extensive testing in order to surpass the industry standards. We offer sizes varying from 65 gallon to 800 gallon tanks. Along with tanks we manufacture customizable stands.

Plas-Tanks Industries fabricates fiberglass-reinforced plastic tanks, chemical tanks (for storage) and vacuum vessels for storage, processing and mixing of water, wastewater and corrosive materials. We specialize in repairs, shop design and fabrication plus shop-built and field-assembled vessels.

Rhino Tuff Tanks is a leading manufacturer of high density polyethylene plastic tanks. Our tanks are built to last and can easily replace 55 gallon drums and steel tanks while conserving space by stacking vertically. Rhino Tuff Tanks can be used to store fluids across a wide variety of industries, including automotive liquids, chemical fluids, farm and agricultural fluids, and industrial fluids....

More Septic Tank Manufacturers

A plastic septic tank is a type of septic tank that is made of high-density polyethylene (HDPE) or other types of plastic. They were first introduced in the 1970s and have become increasingly popular due to their ease of installation, durability, and resistance to corrosion.

How do Plastic Septic Tanks Function?

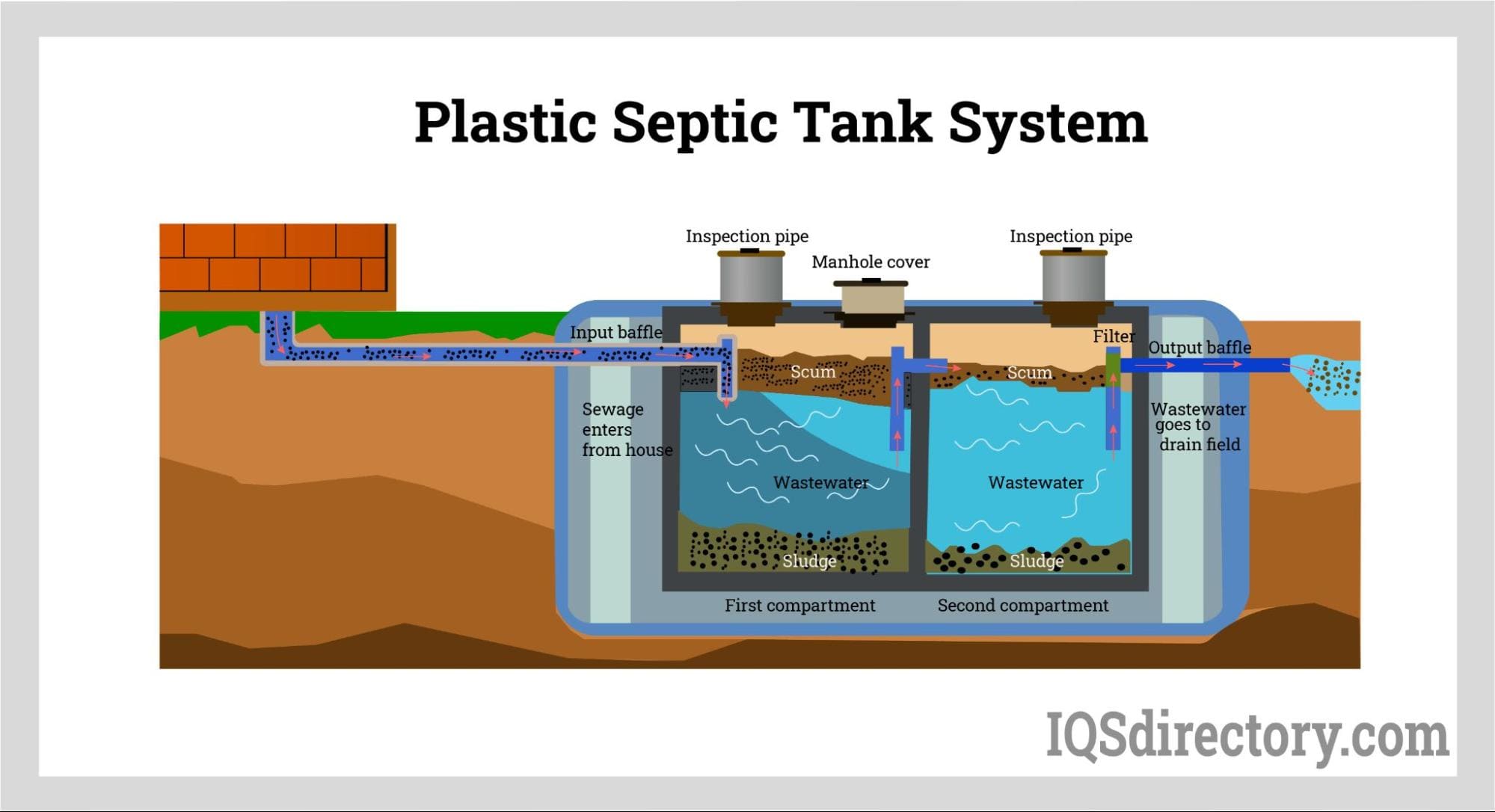

Septic tanks function by separating solid waste from liquid waste. When wastewater enters the tank, it settles into three layers: solids sink to the bottom, a layer of scum floats to the top, and the liquid in the middle is discharged into the drain field. The bacteria in the tank break down the solids, turning them into sludge, which is then pumped out periodically. Plastic septic tanks function in the same way as traditional septic tanks. They have an inlet and outlet pipe and a baffle to separate the solid and liquid layers. However, they are lighter and easier to install than traditional concrete or steel septic tanks.

Are There Limitations to Plastic Septic Tanks?

One limitation of septic tanks in general is their capacity. They can only hold a certain amount of wastewater, and if they become too full, they can overflow or cause backups in the plumbing system. Additionally, septic tanks require regular maintenance, including pumping and inspection, to ensure that they are working properly. The specific limitations of plastic septic tanks include their vulnerability to damage from heavy equipment or shifting soil. They also have a lower resistance to heat than concrete or steel tanks and may be more prone to cracking or warping in extreme temperatures.

Are There Negatives Relating to Plastic Septic Tanks?

One negative associated with septic tanks in general is the potential for groundwater contamination. If a septic tank is not functioning properly or is located too close to a well or other water source, it can contaminate the groundwater with bacteria, viruses, and other harmful substances. Additionally, septic tanks can emit unpleasant odors if they are not properly maintained. The specific negative associated with plastic septic tanks is their vulnerability to UV radiation. If exposed to sunlight for extended periods, the plastic can degrade and become brittle, which can lead to leaks or other damage.

Are There Regulations for Plastic Septic Tanks?

In the United States, the use of plastic septic tanks is regulated by both federal and state authorities. These regulations ensure that plastic septic tanks are safe and effective for their intended use and that they comply with environmental and public health standards. Here are some of the regulations that apply to plastic septic tanks in the United States:

NSF/ANSI Standard 46: This is a national standard that sets performance and testing requirements for septic tanks and other onsite wastewater treatment systems. Plastic septic tanks that comply with this standard have been tested and certified to meet specific design and performance requirements.

State regulations: Each state has its own regulations regarding the use of plastic septic tanks. For example, some states may require that plastic septic tanks be installed only in certain soil types, while others may require specific certifications or approvals before installation.

Environmental Protection Agency (EPA) regulations: The EPA sets federal regulations for septic systems, including plastic septic tanks. These regulations include standards for system design, construction, operation, and maintenance, as well as requirements for groundwater protection and public health.

Local regulations: Local authorities such as county or city governments may also have regulations regarding the use of plastic septic tanks. These regulations may include requirements for permits, inspections, and maintenance.

Overall, it is important to check with local and state authorities before installing a plastic septic tank to ensure compliance with all applicable regulations. In addition, it is recommended to choose a tank that has been tested and certified to meet the appropriate standards, such as NSF/ANSI Standard 46. Proper installation and maintenance of the tank can also help ensure compliance with regulations and protect public health and the environment.

What Are the Benefits of Plastic Septic Tanks?

Cost-effective: Septic tanks are relatively inexpensive to install and maintain compared to centralized sewer systems. Plastic septic tanks are typically less expensive than concrete and fiberglass tanks.

Easy installation: Septic tanks are easy to install and require minimal excavation.

Environmentally friendly: Septic tanks treat wastewater on-site, which means that they reduce the amount of wastewater that is discharged into the environment.

Low maintenance: Septic tanks require minimal maintenance, typically needing to be pumped out every three to five years.

Flexibility: Septic tanks can be customized to meet the needs of specific households and can be adapted to different soil types.

Lightweight: Plastic septic tanks are lighter in weight compared to concrete and fiberglass tanks, which makes them easier to transport and install.

Durable: Plastic septic tanks are resistant to corrosion and rust, making them more durable and longer-lasting than other materials.

Easy to clean: Plastic septic tanks are smooth and easy to clean, reducing the risk of buildup and clogs.

Applications of Plastic Septic Tanks

Residential use: Plastic septic tanks are commonly used for residential purposes due to their durability, cost-effectiveness, and ease of installation.

Commercial use: Plastic septic tanks are also used in commercial settings, such as restaurants and hotels, due to their lightweight and easy installation.

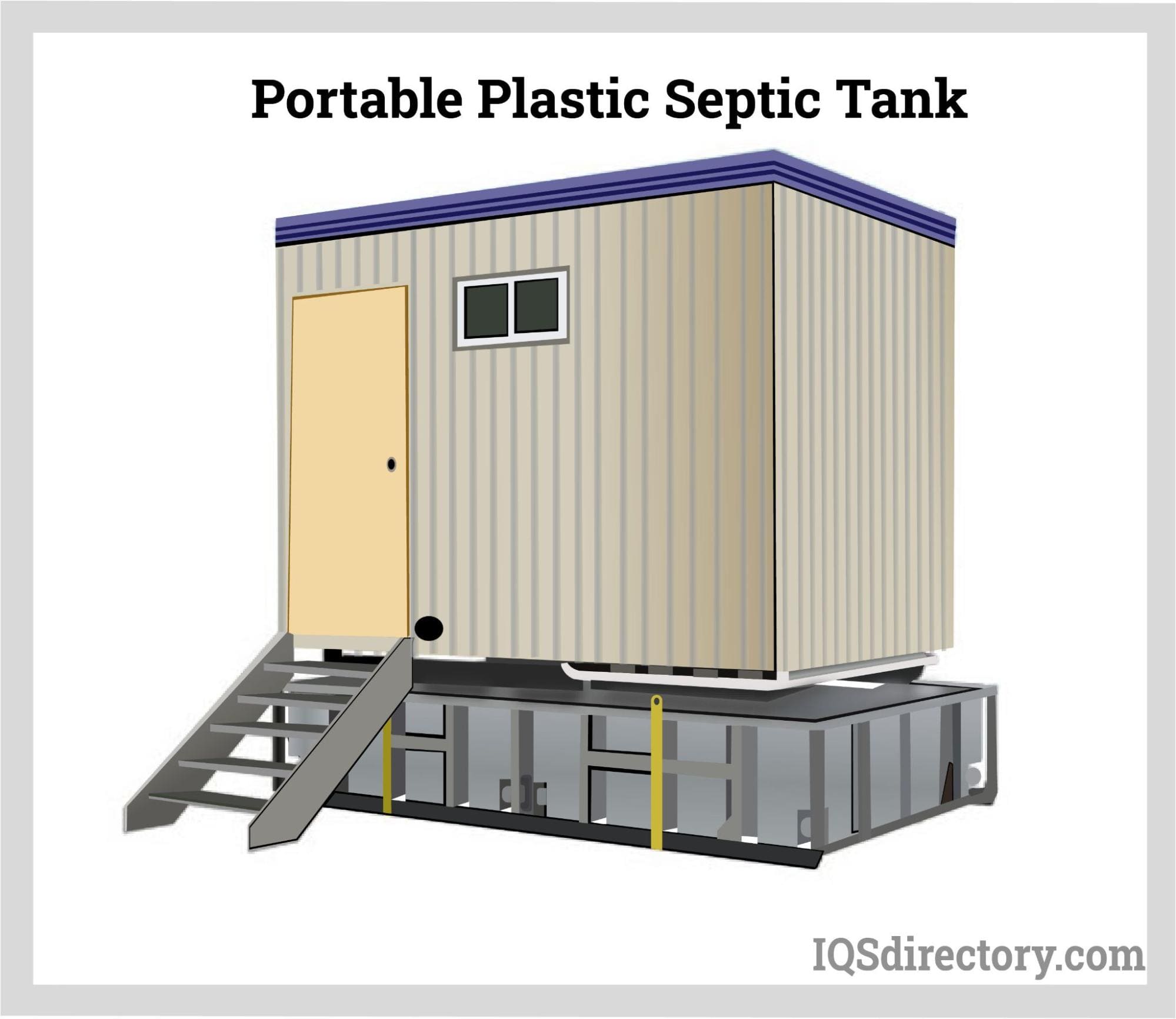

Temporary use: Plastic septic tanks can be used as a temporary solution for construction sites, festivals, and other events due to their portability and ease of installation.

Choosing the Proper Plastic Septic Tank Supplier

To ensure you have the most positive outcome when purchasing a plastic septic tank from a plastic septic tank supplier, it is important to compare several companies using our directory of plastic septic tank suppliers. Each plastic septic tank supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each plastic septic tank business website using our proprietary website previewer to quickly learn what each plastic septic tank company specializes in. Then, use our simple RFQ form to communicate with multiple plastic septic tank companies with the same form.

55 Gallon Drums

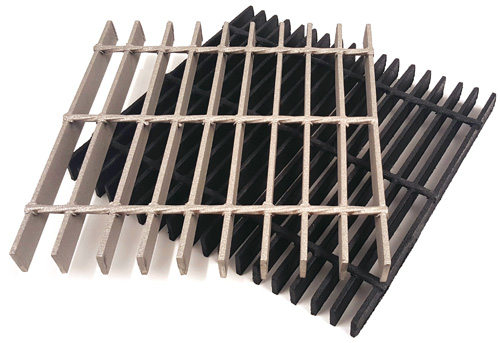

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services