In 1992, the IBC, or intermediate bulk container, or tote, was initially put forth as an alternative to huge cylindrical containers used to transport liquids, chemicals, food, and granular goods. The cylinders were cumbersome,heavy, and challenging to maneuver. When looking for a substitute for the cylinders, shipping companies discovered the IBC tote, which is more lightweight, less expensive, and available in various sizes to suit any shipping requirement. Read More…

Roto Dynamics Inc., custom rotational molders serving rotomolding and plastic tank needs nationwide. We are dedicated to our customers manufacturing needs. Building customer relationships based on integrity and communication assists us in developing a competitive advantage within the industry.

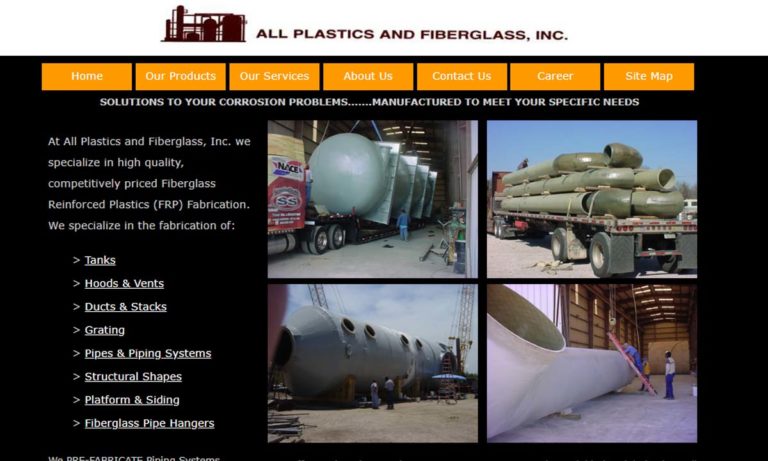

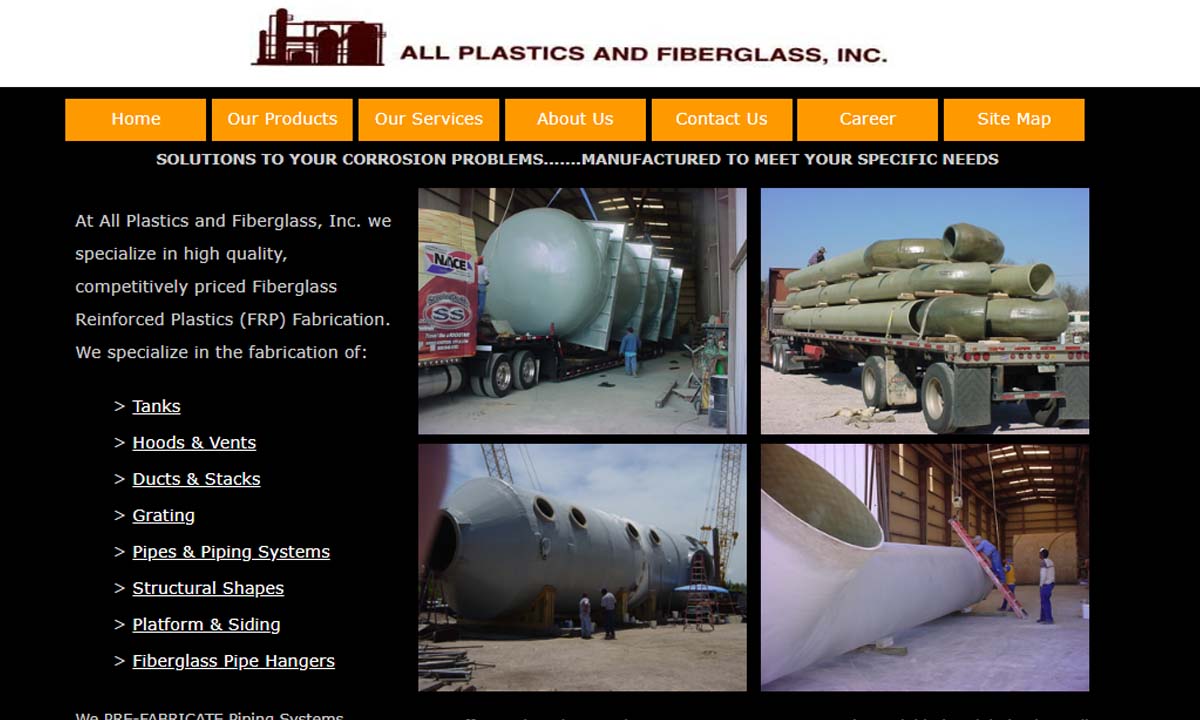

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your plastic and fiberglass needs.

Specializing in fabricated plastic tanks such as water tanks, polypropylene tanks, polyethylene tanks and storage tanks, Park Plastic Products is capable of making your plastic tank in any size or dimension.

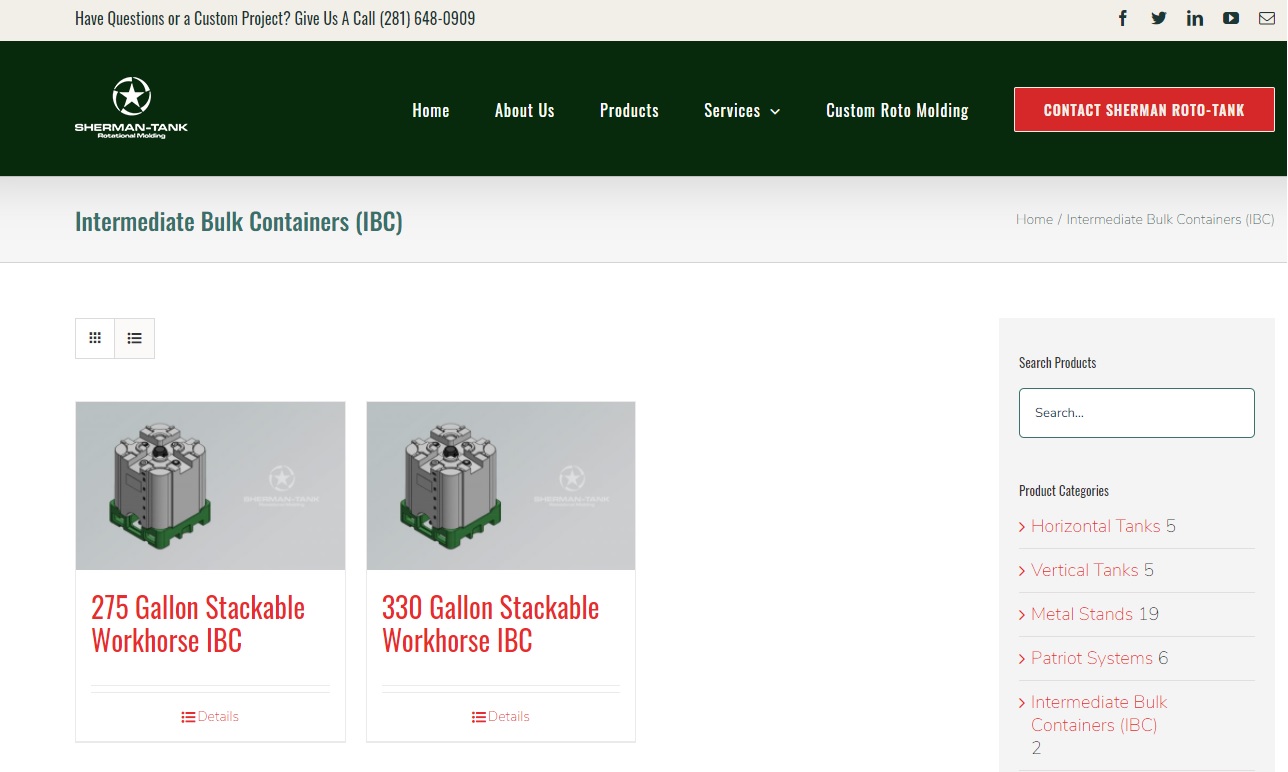

Sherman Roto Tank specializes in tanks that are manufactured to be suitable to store and process chemicals. Our tanks are a great choice for any industry. All our products go through extensive testing in order to surpass the industry standards. We offer sizes varying from 65 gallon to 800 gallon tanks. Along with tanks we manufacture customizable stands.

Plas-Tanks Industries fabricates fiberglass-reinforced plastic tanks, chemical tanks (for storage) and vacuum vessels for storage, processing and mixing of water, wastewater and corrosive materials. We specialize in repairs, shop design and fabrication plus shop-built and field-assembled vessels.

Rhino Tuff Tanks is a leading manufacturer of high density polyethylene plastic tanks. Our tanks are built to last and can easily replace 55 gallon drums and steel tanks while conserving space by stacking vertically. Rhino Tuff Tanks can be used to store fluids across a wide variety of industries, including automotive liquids, chemical fluids, farm and agricultural fluids, and industrial fluids....

More IBC Tote Manufacturers

IBC Tote Design

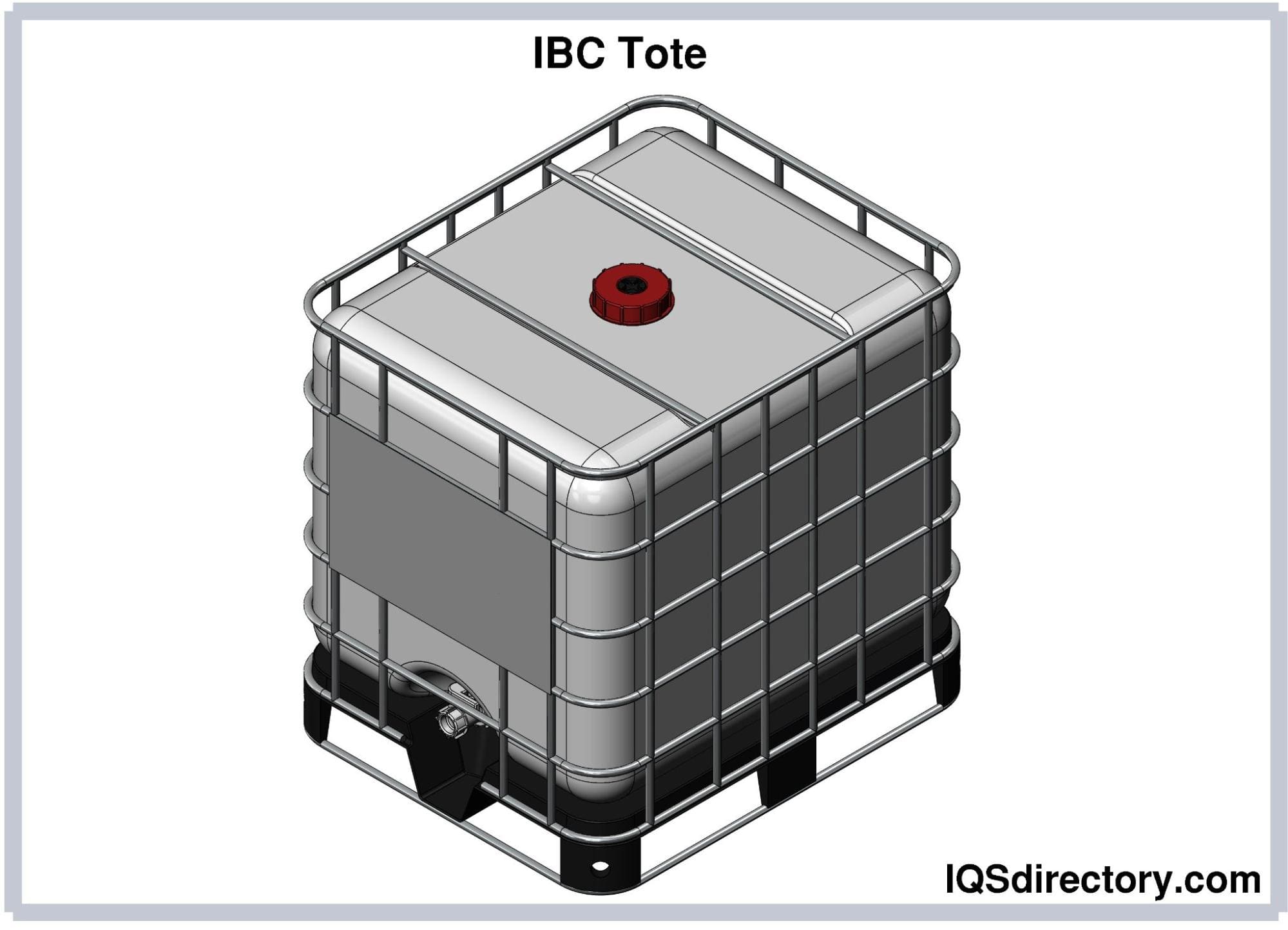

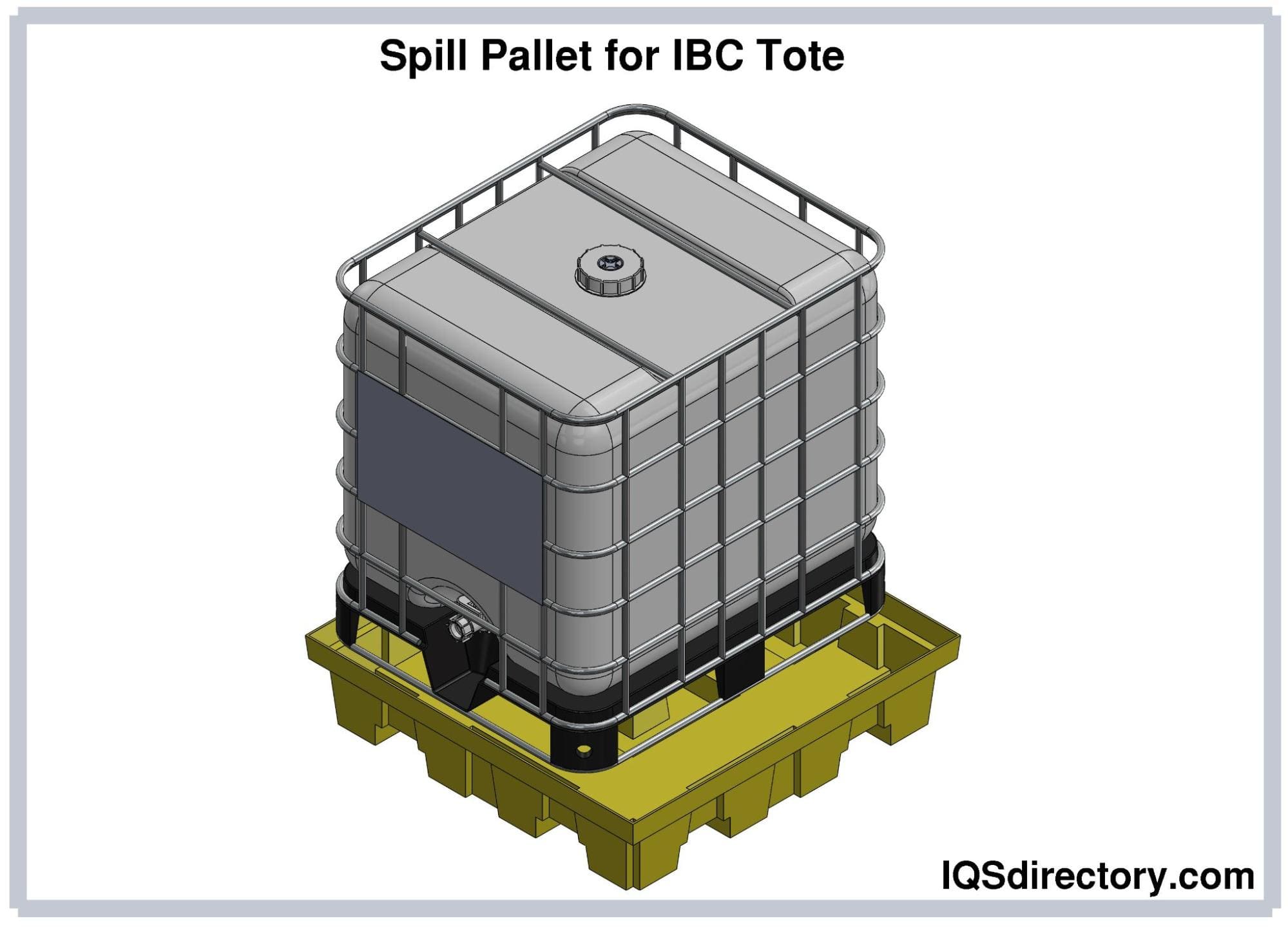

IBC totes are pallet-friendly cube-shaped containers. They can be moved with a pallet jack or forklift for placing in trucks, racks, or railroad wagons. IBC totes are described as intermediate because their size falls between drums and big tanks. They range in size from 120 to 550 gallons and can be adapted to ship hazardous or non-hazardous liquids and chemicals.

An IBC tote tank of tough high-density polyethylene (HDPE) can be built in white or transparent varieties. The tote is encased in a galvanized metal cage fastened to a pallet for easy transportation and transport. Although some IBC bins are intended for single use, most are reusable. How they have been utilized, and the materials they contain will determine how long they will be in use.

Another quality that has contributed to the popularity of intermediate bulk containers as a shipping option is their adaptability. In addition to having a variety of sizes, they are fashioned from a wide range of materials. Several varieties can be folded up for convenient storage when not in use.

Materials for IBC Totes

The material used to make a tote mostly relies on its intended usage. Chemicals, adhesives, detergents, food syrups, powders, granulated food ingredients, and numerous paint kinds are among the materials that can be transported in them.

Although IBC Totes are most frequently manufactured of HDPE plastic, they can also be produced from wood, steel, aluminum, and fiberglass. As a result, producers can alter the tote to meet the shipping requirements of a customer thanks to the variety of materials available. In addition, producers can create a tote properly tailored to a customer's needs if the normal sizes are insufficient.

Maintenance of IBC Totes

An IBC can be considered a returnable vessel and reused for several shipments for many applications, such as food components. However, they need to be thoroughly cleaned after every usage when they are used as reusable vessels, and any contamination could compromise the quality of the subsequent filling. Clean-in-place (CIP) and clean-out-of-place (COP) are two frequently used cleaning techniques. These terms describe whether mobile equipment will be mounted to the container to finish the cleaning operation or if the container will be relocated to another place for cleaning.

Parts of IBC Totes

Drums: The main component of the IBC and what retains the contents inside is the drum, commonly referred to as a barrel. Typically, a steel grid is placed over the thick plastic drum to add additional support. However, carbon steel and stainless steel can also make the drum.

Pallets: These items have pallets on the bottom to aid in moving IBCs around and stacking them on top of one another. Plastic, wood, and metal are just a few materials used to make pallets. Additionally, this component raises the IBC tank off the ground, allowing air to flow underneath it and allowing machines to easily lift the tank when it is full and needs to be removed.

Valves: Another essential component of IBC tanks is the valve, which lets users remove liquids and other similar materials from the inside without producing a mess. IBC valves normally include a hole on the front through which a hose can be connected to securely transfer the contents inside to another container. IBC valves will come in various forms, some controlling the flow of liquids with locking handles and others with screw-on caps.

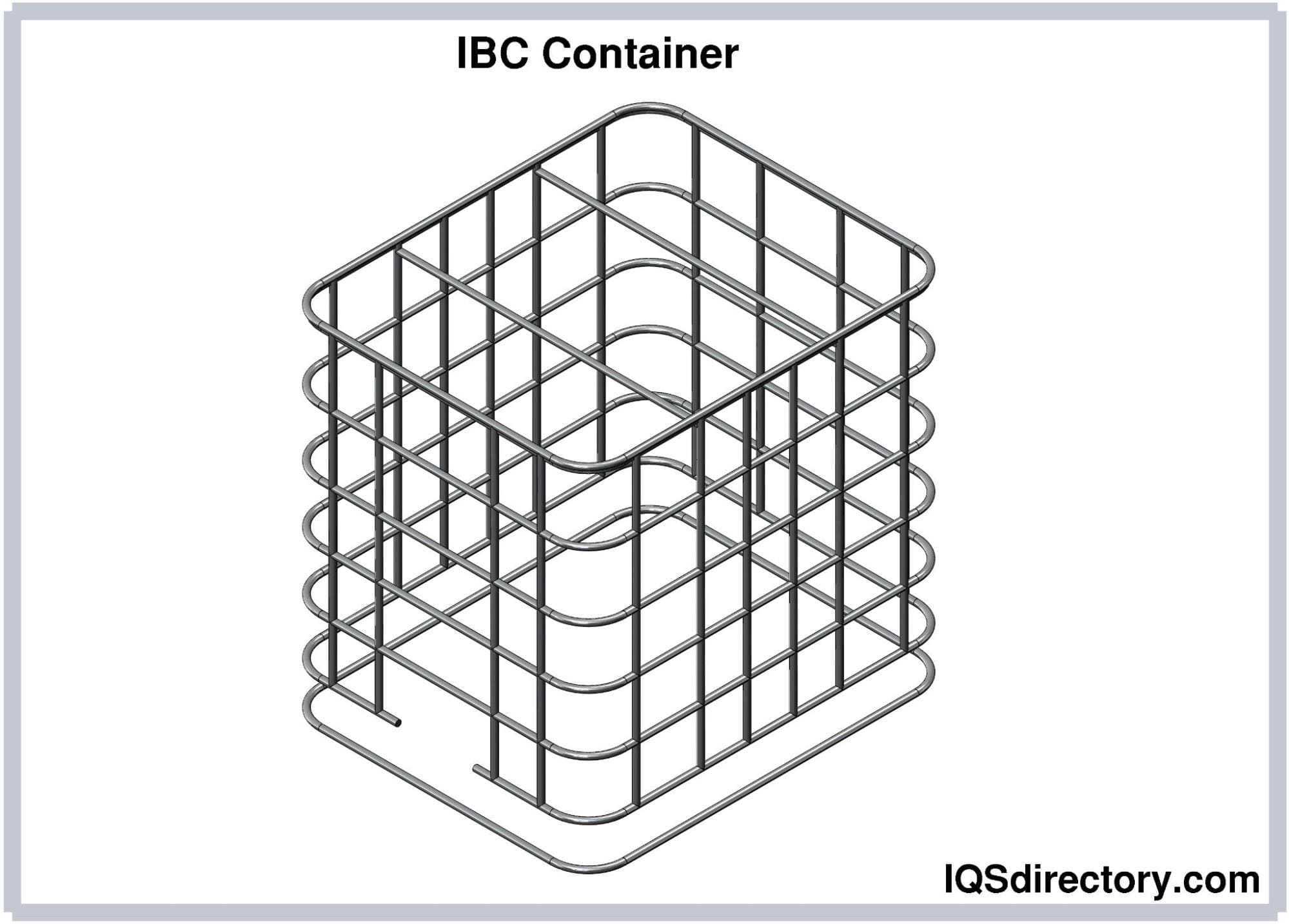

Metal Cages: IBCs made of plastic are frequently encased in a steel cage. Metal cages help maintain an IBC tote’s balance when placing contents inside. In addition, the outside is shielded from being pierced or otherwise harmed.

Clamps: Clamps are employed to provide pressure to stop liquid from seeping out of the IBC valves and, occasionally, the drum itself. These gadgets typically have a locking mechanism on the front to keep them in place.

Gauges: Gauges are tools that employees can use to “gauge” the volume of the IBC's contents. Depending on how thoroughly customers wish to inspect the interior of the IBC tank and how big the IBC tank is, this product's characteristics vary. Gauges typically include a dial on top that notifies of the measures recorded and are composed of carbon steel or aluminum.

Benefits of IBC Totes

The flexibility and adaptability of intermediate bulk containers is the major driver behind their development. Spouts, drains, and valves that are precisely sized for the contents being sent may be designed to meet the needs of every shipping necessity. Their invention has allowed us to do away with the need for large containers for medium-sized quantities. Totes can be manufactured to accommodate every transportation method, from trucks to trains to planes, because they are available in several sizes. This one feature has mostly driven their use and appeal.

Choosing the Correct IBC Tote Supplier

To ensure you have the most beneficial outcome when purchasing IBC totes from an IBC tote supplier, it is important to compare several companies using our directory of IBC tote suppliers. Each IBC tote supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each IBC tote business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple IBC tote companies with the same form.

55 Gallon Drums

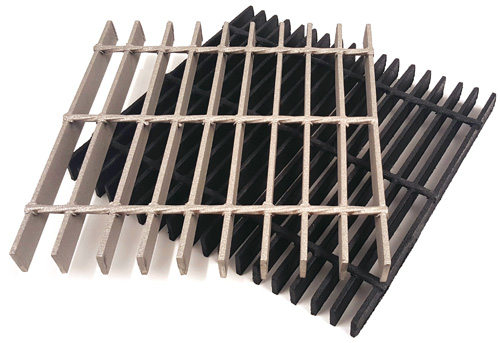

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services