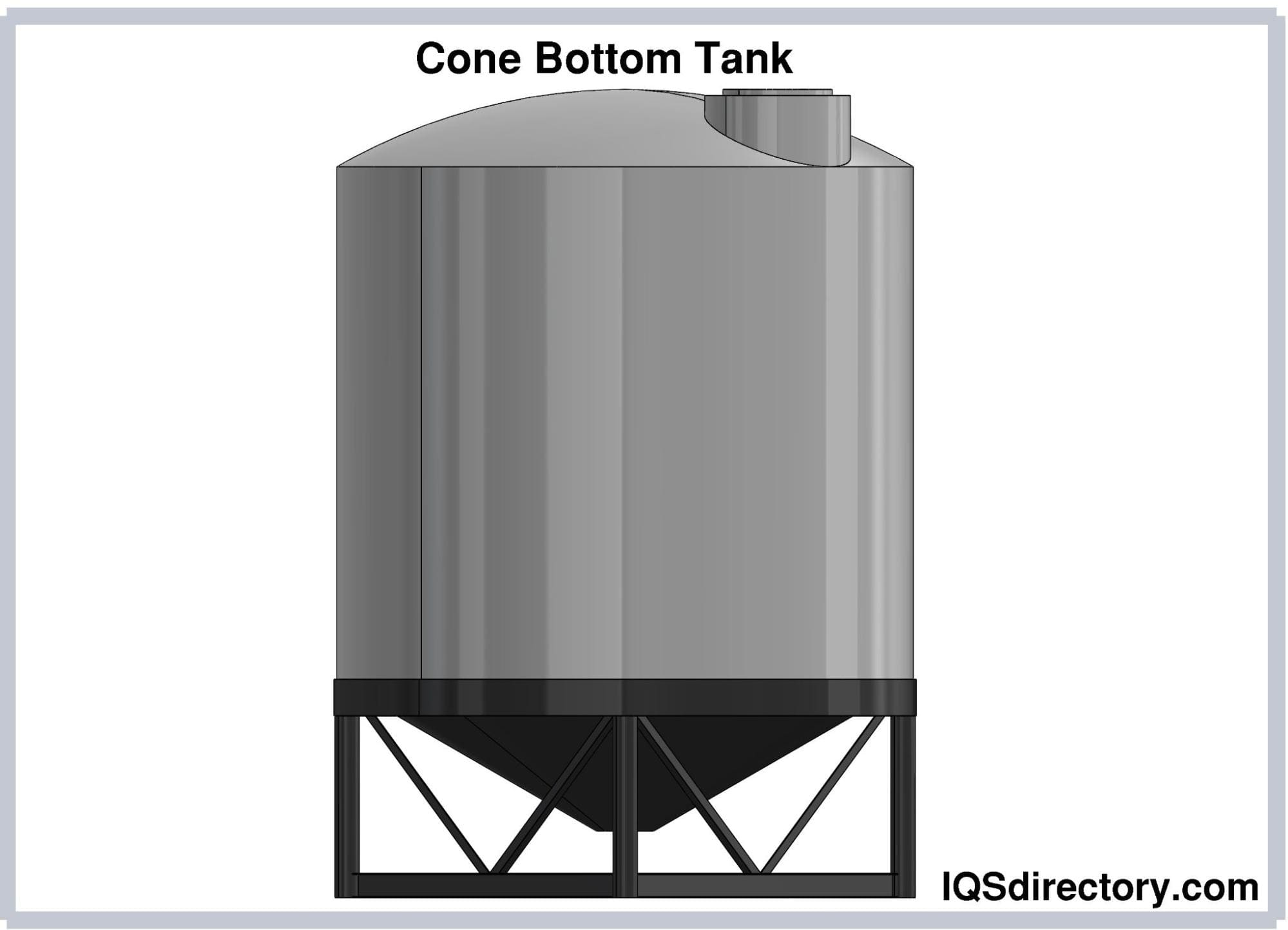

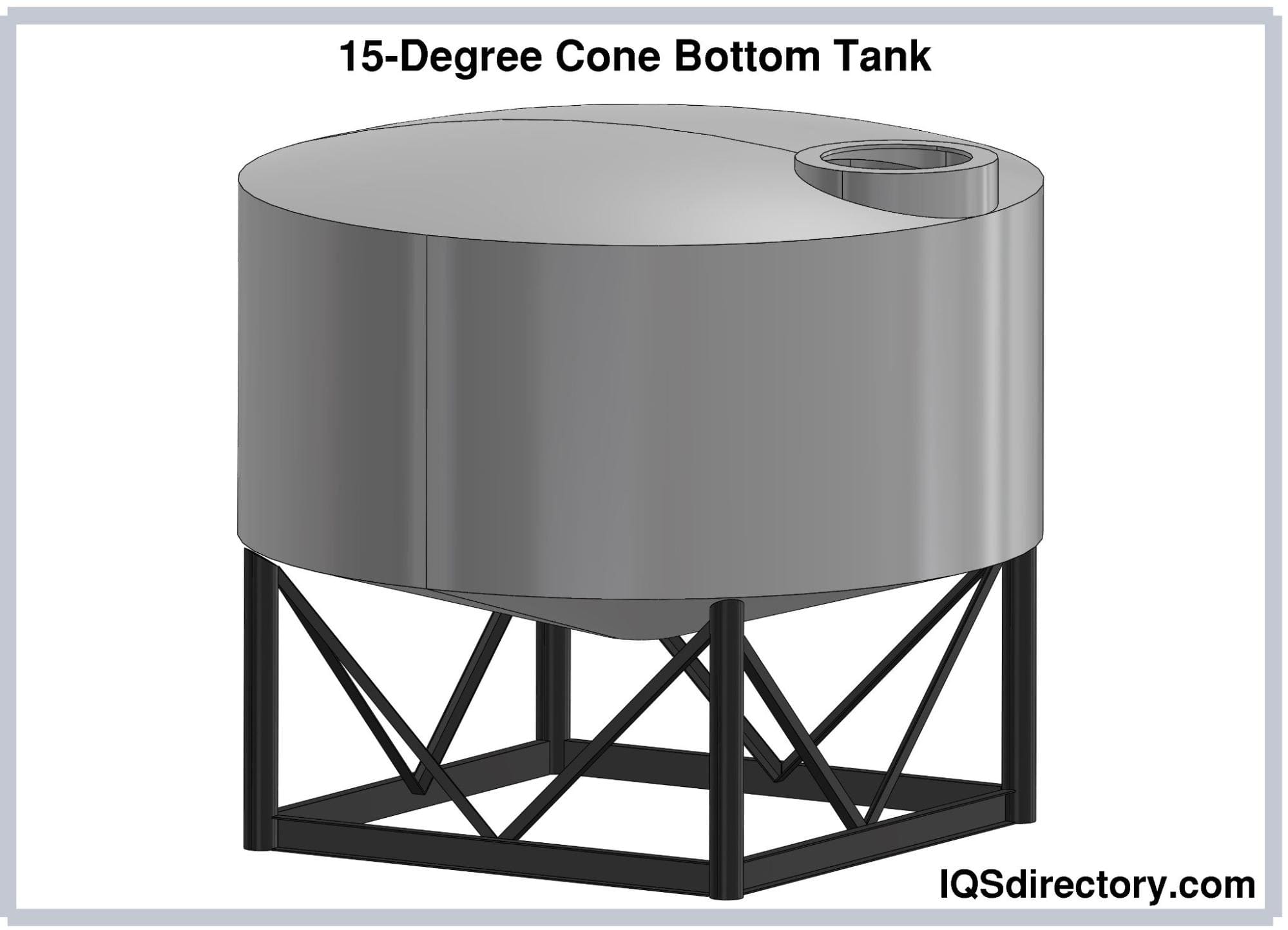

Cone bottom tanks are plastic containers with conical, angled, or pointed bottoms. This distinctive quality serves a useful purpose. Tanks with a conical bottom offer complete drainage for applications where every drop of liquid must be removed from a tank. Cone bottom tanks are offered with different slopes. There are slopes available at 30°, 45°, and 60° in addition to the regular slope of 90°. Read More…

Roto Dynamics Inc., custom rotational molders serving rotomolding and plastic tank needs nationwide. We are dedicated to our customers manufacturing needs. Building customer relationships based on integrity and communication assists us in developing a competitive advantage within the industry.

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your plastic and fiberglass needs.

Specializing in fabricated plastic tanks such as water tanks, polypropylene tanks, polyethylene tanks and storage tanks, Park Plastic Products is capable of making your plastic tank in any size or dimension.

Sherman Roto Tank specializes in tanks that are manufactured to be suitable to store and process chemicals. Our tanks are a great choice for any industry. All our products go through extensive testing in order to surpass the industry standards. We offer sizes varying from 65 gallon to 800 gallon tanks. Along with tanks we manufacture customizable stands.

Plas-Tanks Industries fabricates fiberglass-reinforced plastic tanks, chemical tanks (for storage) and vacuum vessels for storage, processing and mixing of water, wastewater and corrosive materials. We specialize in repairs, shop design and fabrication plus shop-built and field-assembled vessels.

Rhino Tuff Tanks is a leading manufacturer of high density polyethylene plastic tanks. Our tanks are built to last and can easily replace 55 gallon drums and steel tanks while conserving space by stacking vertically. Rhino Tuff Tanks can be used to store fluids across a wide variety of industries, including automotive liquids, chemical fluids, farm and agricultural fluids, and industrial fluids....

More Cone Bottom Tank Manufacturers

Tanks with cone bottoms cannot stand up straight due to their sloping bottoms. Stands therefore support the tanks. Different stands are available depending on the weight and dimensions of the tank. Tank stands made of carbon, or stainless steel pipework, support heavier and greater tanks. For smaller, lighter tanks, fiberglass or plastic stands are preferable.

Uses of Cone Bottom Tanks

Cone bottom tanks, often white, are frequently made of sturdy, long-lasting plastic materials like polypropylene or polyethylene, depending on their contents. High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are specific varieties of polyethylene that are often utilized. Cone bottom tanks can also store anything from 15 to 13,000 gallons. Water storage, wine fermentation, biodiesel, and fuel storage for sectors like wastewater, chemical processing, industrial production, and automobile production are a few of their popular uses.

In addition, cone bottom tanks that have received approval from the Food and Drug Administration (FDA) are frequently used in the food processing industry and medical processes like hemodialysis, buffer mixing, reverse osmosis and blending.

Despite having cone-shaped bottoms, these tanks can have a variety of top shapes. The flanged rim, closed flat top, closed dome, and open top with a 90° angle are among these shapes. Cone bottom tanks are utilized in various sectors and may operate in indoor and outdoor locations thanks to the resilience of the materials used in their creation.

Grades of Cone Bottom Tanks

Industrial Grade

These kinds of tanks are utilized for applications at high altitudes as well as for the containment of extremely hostile acids and caustics. As a result, they must have walls that are thicker than those of a standard tank and that are made of sturdy, corrosion-resistant materials.

Commercial Grade

These tanks are designed to handle far less aggressive compounds than suited for industrial grade tanks. Because of this, the specifications for creating these tanks, such as the preferred material for the tank or the thickness of the walls, are significantly less stringent. As a result, commercial-grade tanks are frequently used in the food processing sector.

Standard Grade

These tanks are the smallest and lowest weight of the three types. They are made to process and store things like agricultural chemicals, extremely aqueous solutions, and drinkable water.

Design of Cone Bottom Tanks

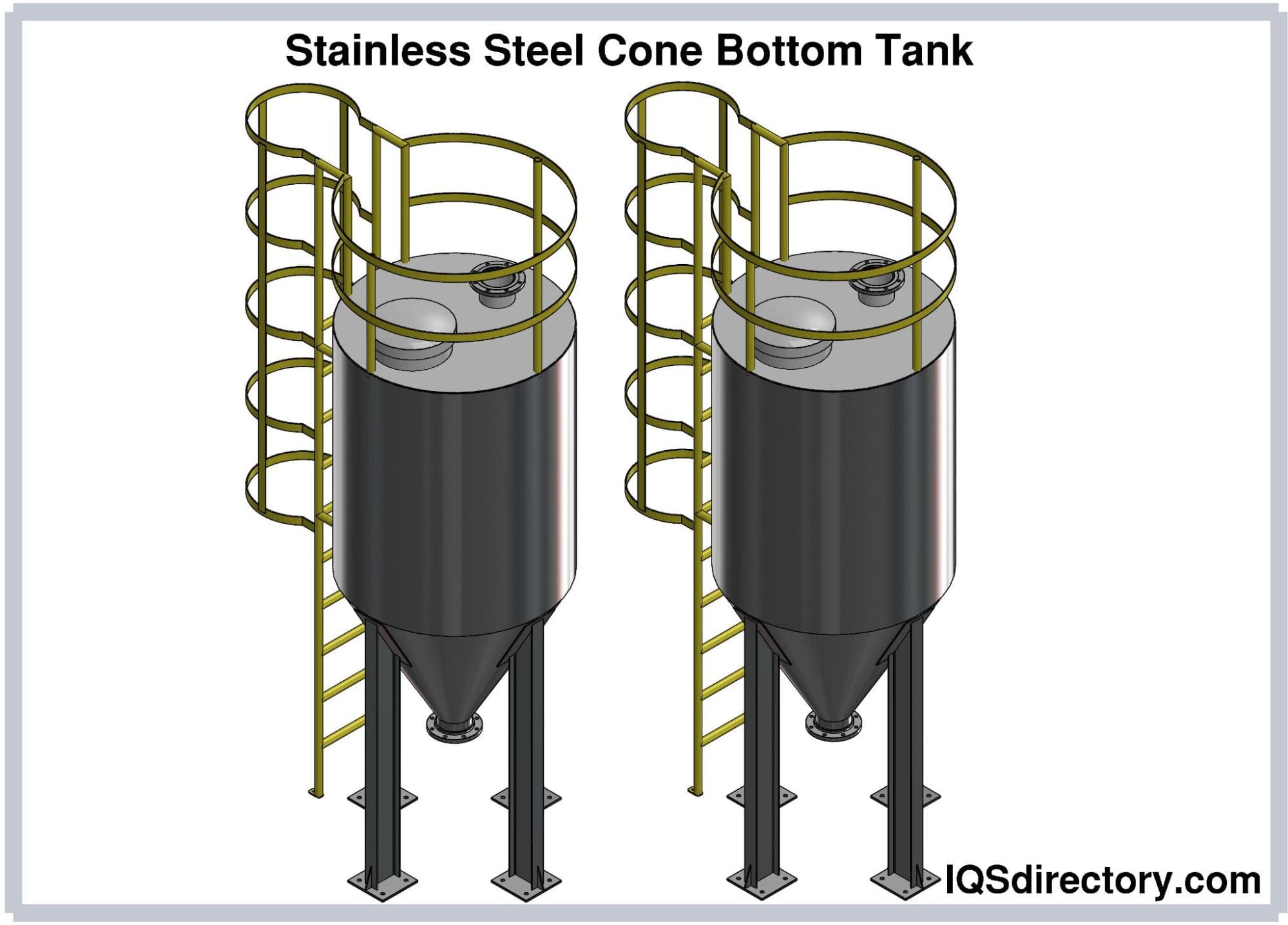

Cone bottom tanks are measured in gallons and they can also be manufactured of metal, fiberglass, and plastic. Due to its hygienic qualities and resistance to corrosion and rust, stainless steel is the most popular metal used to create cone-bottom tanks. Fiberglass has a unique combination of advantages. It is robust, affordable, and incredibly adaptable. At first look, fiberglass and stainless steel cone bottom tanks could seem equally as durable, if not more so, than those made of plastic.

However, the three materials' most favorable characteristics are found in plastic. Plastic is lighter than stainless steel and fiberglass, making the tank easier to move and erect. The most flexible tanks have plastic cone bottoms and thicker side walls. The tanks' walls are typically half an inch thicker than fiberglass. Even though it might appear trivial, this tiny portion has a major impact. Plastic cone bottom tanks with thicker walls may withstand more impacts without harm. Not all fittings installed through the welding process are cleaned and treated after completion, which is possible with stainless steel tanks.

As a result, the tank's longevity may be impacted by the welds' susceptibility to corrosion. The periodic inspection of fiberglass tanks is necessary since they are not impervious to corrosion. However, poly tanks are impervious to all these dangerous substances, eliminating the need for time-consuming inspection. Metal and fiberglass tanks are made with welds and seams, which may increase the likelihood of a leak. Since poly tanks are produced without seams, this risk is eliminated. Plastic is generally the most dependable material for cone-bottom tanks.

Choosing the Right Cone Bottom Tank Manufacturer

To ensure you have the most productive outcome when purchasing a cone bottom tank from a cone bottom tank manufacturer, it is important to compare several companies using our directory of cone bottom tank manufacturers. Each cone bottom tank manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to communicate with the manufacturer for more information or request a quote. Review each cone bottom tank business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to communicate with multiple cone bottom tank companies with the same form.

55 Gallon Drums

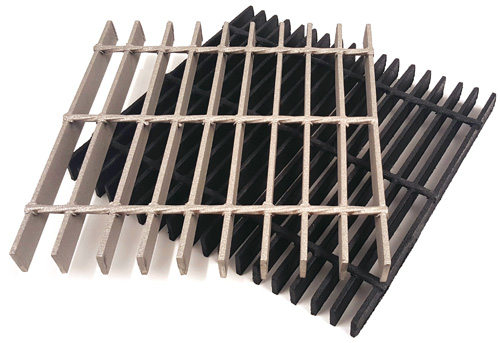

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services