The most common flammable substance that is typically stored in plastic fuel tanks is gasoline or fuel; however other flammable substances such as butane, motor oil, transformer oil, gas oil and natural gas can also be stored. Read More…

Roto Dynamics Inc., custom rotational molders serving rotomolding and plastic tank needs nationwide. We are dedicated to our customers manufacturing needs. Building customer relationships based on integrity and communication assists us in developing a competitive advantage within the industry.

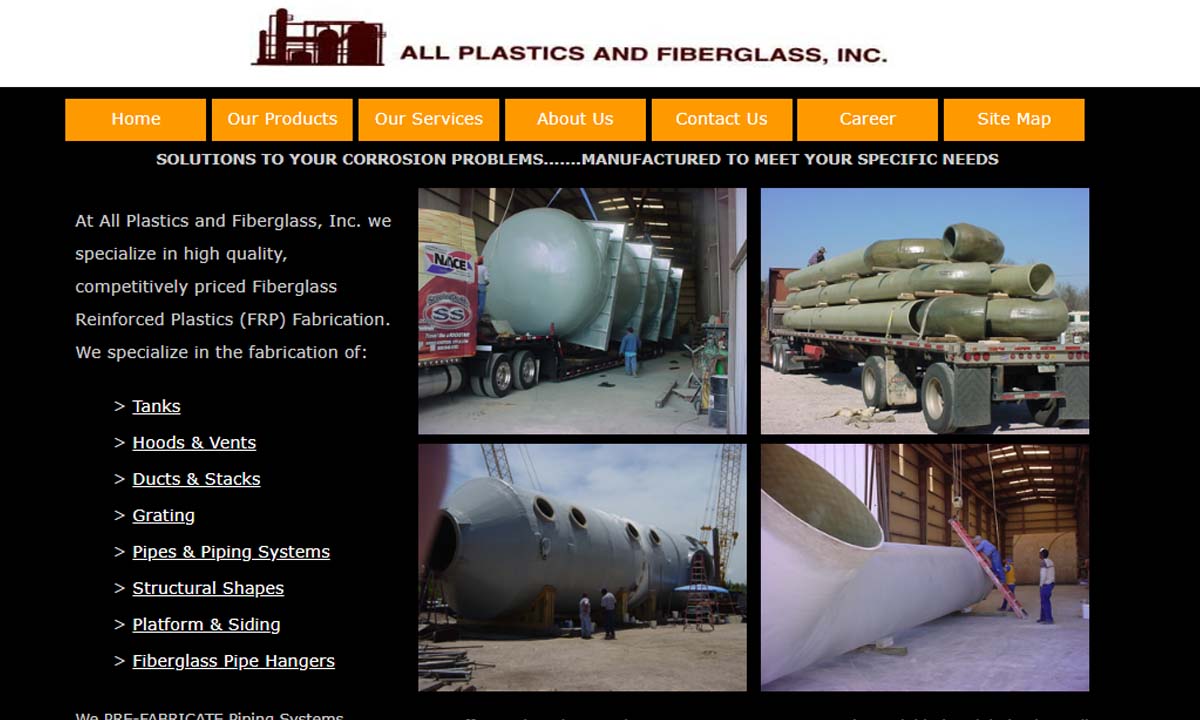

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your plastic and fiberglass needs.

Specializing in fabricated plastic tanks such as water tanks, polypropylene tanks, polyethylene tanks and storage tanks, Park Plastic Products is capable of making your plastic tank in any size or dimension.

Sherman Roto Tank specializes in tanks that are manufactured to be suitable to store and process chemicals. Our tanks are a great choice for any industry. All our products go through extensive testing in order to surpass the industry standards. We offer sizes varying from 65 gallon to 800 gallon tanks. Along with tanks we manufacture customizable stands.

Plas-Tanks Industries fabricates fiberglass-reinforced plastic tanks, chemical tanks (for storage) and vacuum vessels for storage, processing and mixing of water, wastewater and corrosive materials. We specialize in repairs, shop design and fabrication plus shop-built and field-assembled vessels.

Rhino Tuff Tanks is a leading manufacturer of high density polyethylene plastic tanks. Our tanks are built to last and can easily replace 55 gallon drums and steel tanks while conserving space by stacking vertically. Rhino Tuff Tanks can be used to store fluids across a wide variety of industries, including automotive liquids, chemical fluids, farm and agricultural fluids, and industrial fluids....

More Plastic Fuel Tank Manufacturers

Plastic fuel tanks have numerous advantages over metal fuel tanks. These advantages include being lighter weight than most metals, more durable, offer improved compartment space utilization, increased convenience, cost-efficiency and safety due to being non-explosive. Plastic fuel tanks are also flexible, which allows for the expansion of vapors and bending during an accident.

Plastic fuel tanks can be a part of the engine system where the fuel is stored and propelled by a fuel pump in, or released into an engine in cars, trucks, motorcycles, AGVs, boats and more, they can be stationary above ground or they can be manually transported by hand. Plastic fuel tanks are essential in industries such as automotive, aerospace, construction, industrial, commercial, petroleum, marine and military. Typical configurations of plastic fuel tanks include rectangular, cone bottoms, horizontal, cylindrical and vertical.

Poly fuel tanks are molded into a seamless one-piece construction that typically consists of at least six layers of a given material, or several different materials that provide different beneficial characteristics. Typically, plastic fuel tanks are made from these five different materials: high density polyethylene (HDPE), polypropylene (PP), regrind plastic (recycled polyethylene), a plastic adhesive or ethyl vinyl alcohol (EVOH).

These storage tanks can be formed by rational molding or blow molding processes. The rotational molding process begins with a heated mold that causes the plastic within to melt; thus forming a puddle at the bottom of the mold cavity. Next, the mold is slowly rotated, usually around two perpendicular axes, resulting in the melted plastic flowing into the mold and sticking to its walls.

The last part is the cooling phase in which the mold continues to rotate so that an even thickness is maintained throughout the gas tank. The blow molding process begins with melting down the plastic and forming it into a parison, a tube-like piece of plastic with a hole in one end in which compressed air can pass through.

Next, a pressurized gas, usually air, is used to expand the hot parison and press it against a mold cavity. The pressure is held until the plastic is cooled. Once the plastic is cool and hardened the mold opens up and the part is ejected. Rotationally molded plastic fuel tanks will be stronger; whereas blow molded plastic fuel tanks will be more susceptible to weakness in the walls.

55 Gallon Drums

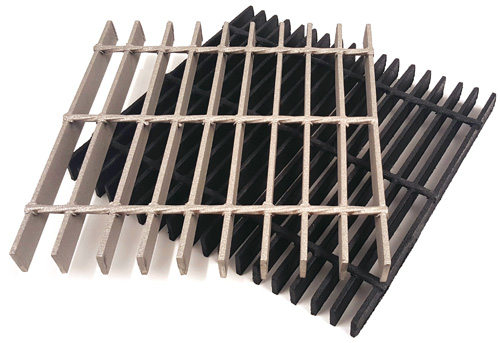

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services