In addition to material choice, storage tanks differ in size and capacity, ranging from small tanks holding a few gallons to tanks exceeding 35 feet in length, with a storage capacity of 50,000 gallons or more. Read More…

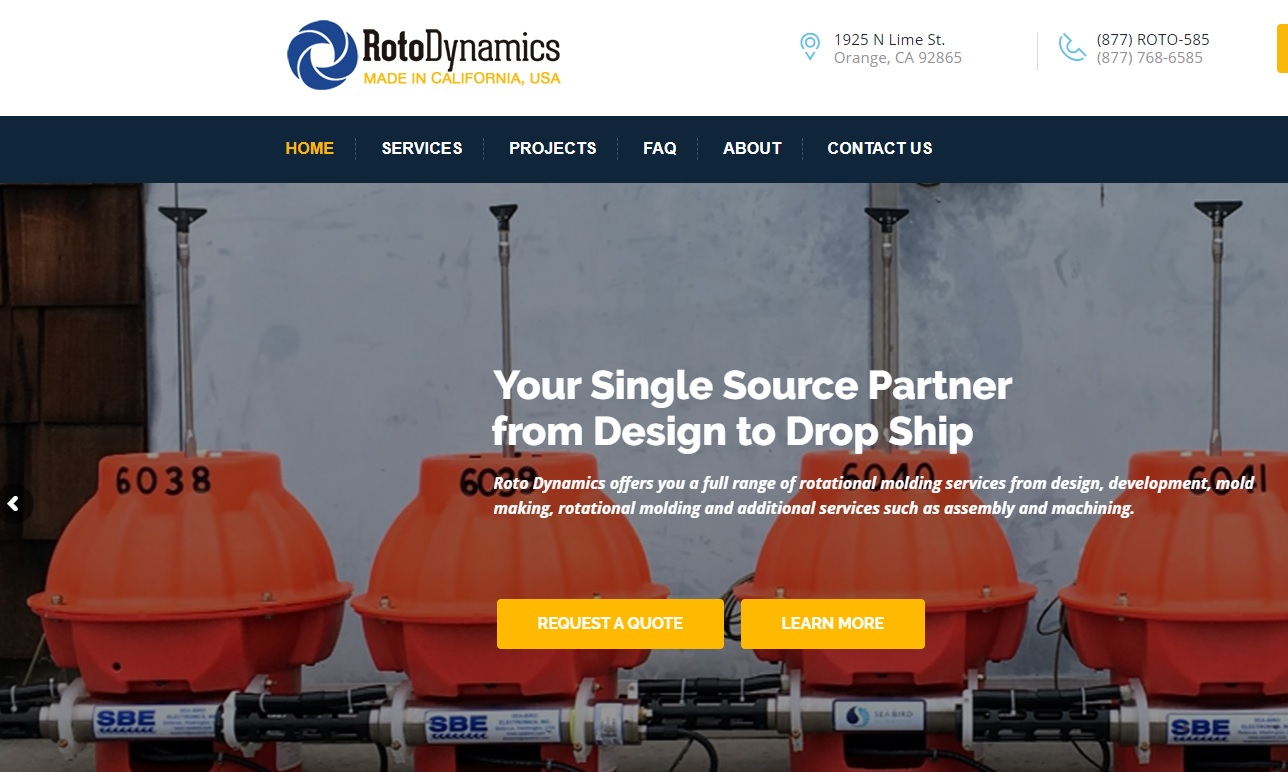

Roto Dynamics Inc., custom rotational molders serving rotomolding and plastic tank needs nationwide. We are dedicated to our customers manufacturing needs. Building customer relationships based on integrity and communication assists us in developing a competitive advantage within the industry.

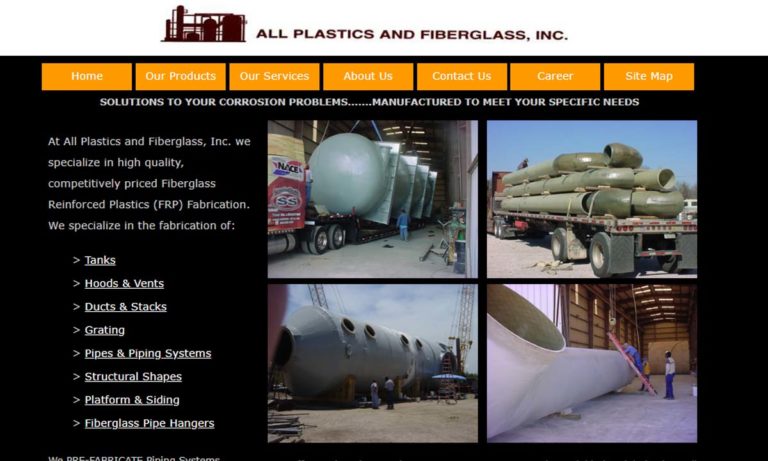

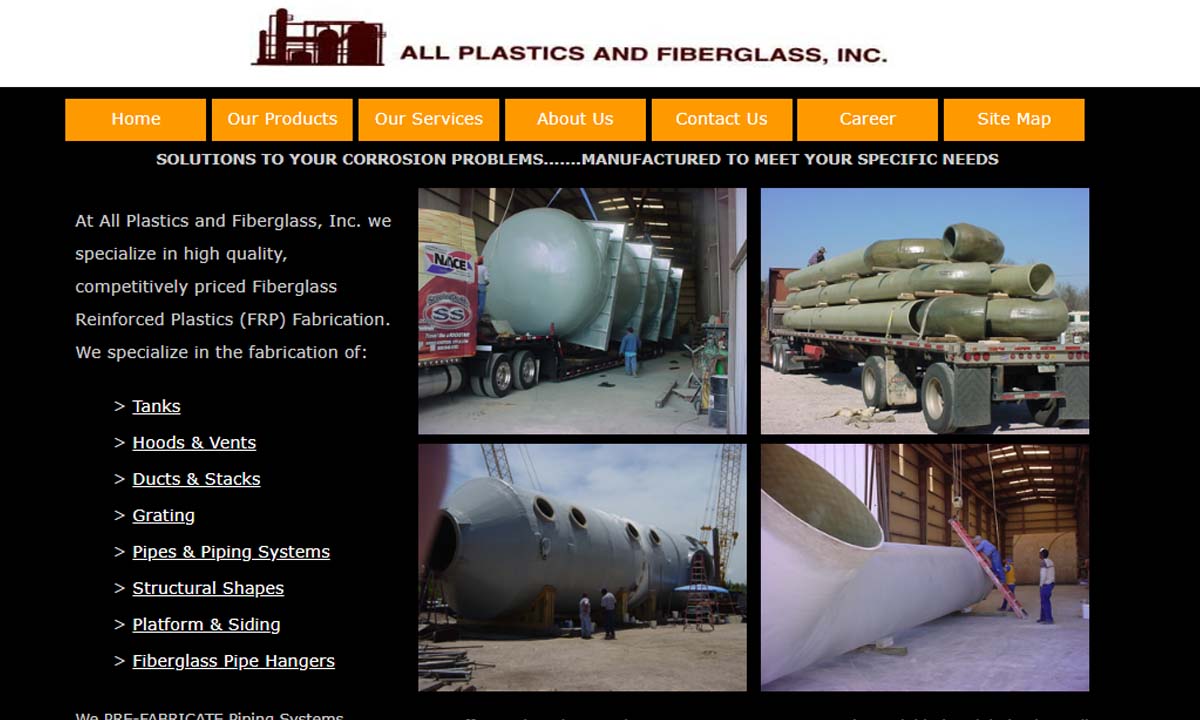

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your plastic and fiberglass needs.

Specializing in fabricated plastic tanks such as water tanks, polypropylene tanks, polyethylene tanks and storage tanks, Park Plastic Products is capable of making your plastic tank in any size or dimension.

Sherman Roto Tank specializes in tanks that are manufactured to be suitable to store and process chemicals. Our tanks are a great choice for any industry. All our products go through extensive testing in order to surpass the industry standards. We offer sizes varying from 65 gallon to 800 gallon tanks. Along with tanks we manufacture customizable stands.

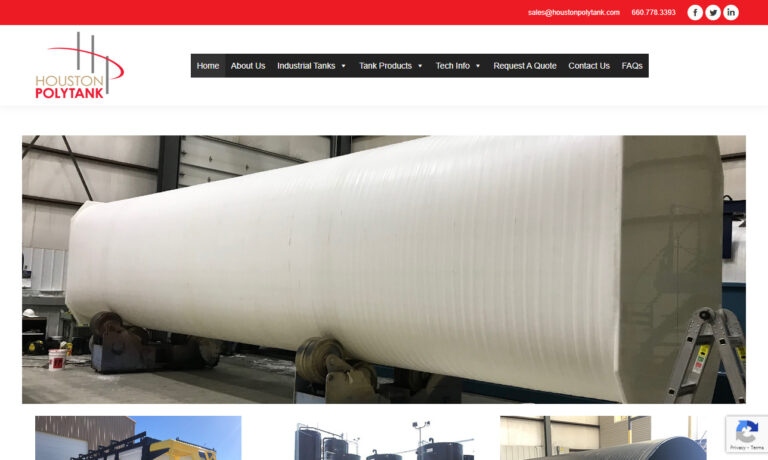

Houston PolyTank offers industrial tanks produced by wrapping bands of compressed plastic around a pre-heated mandrel, thus forming a homogeneous tank. Our cylindrical tanks store up to 50,000-gallons in capacity and our patented rectangular tanks store up to 18,000-gallons. Our industrial tanks are made of polypropylene and are heat-resistant up to 180°F. The plastic is corrosion- and...

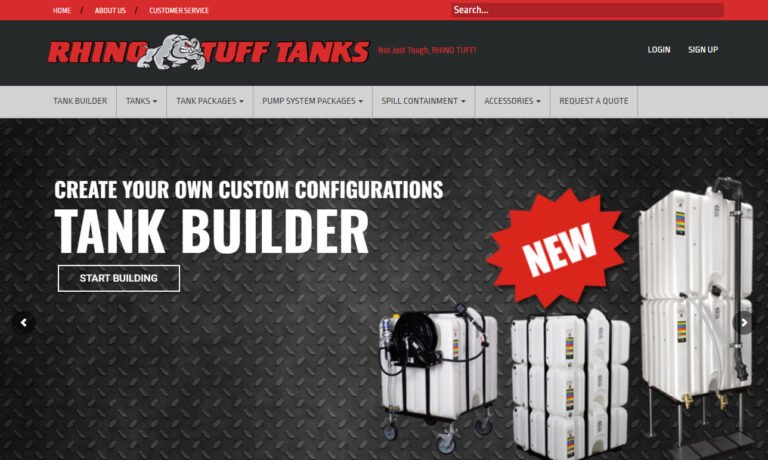

Rhino Tuff Tanks is a leading manufacturer of high density polyethylene plastic tanks. Our tanks are built to last and can easily replace 55 gallon drums and steel tanks while conserving space by stacking vertically. Rhino Tuff Tanks can be used to store fluids across a wide variety of industries, including automotive liquids, chemical fluids, farm and agricultural fluids, and industrial fluids....

More Storage Tank Manufacturers

Storage tanks encompass a very broad category, and more specific types of storage tanks include water tanks, septic tanks, chemical tanks, fuel tanks, oil tanks and double wall tanks. Due to the wide range of capabilities, storage tanks are utilized in numerous industries including: agricultural, in the storage of water for irrigation as well as herbicides and fertilizer; oil/gas, for the storage of various fuels and oils for automotive and aerospace applications; wastewater treatment, for use in municipal waste water treatment plants and other water treatment facilities; medical, for use in pharmaceutical industries for the storage of liquid and powder medications or even gases such as hydrogen, ammonia, nitrous oxide, carbon dioxide or boron hydride.

Storage tanks are formed using either a molding or a welding process. Plastic tank molding involves using a model shape to form the tank, while plastic tank welding is a process in which two pieces of heat-softened plastic are joined through the application of pressure. Examples of this welding process are hot air and extrusion welding.

In hot air welding, also known as hot gas welding, a specially designed heat gun is used to produce a jet of hot air that functions to soften both the parts that are to be joined and a plastic filler rod, which must all be a similar plastic material. In extrusion welding, a welding rod is drawn into a miniature plastic extruder and then plasticized. After it is plasticized, it is forced out of the extruder and pressed against the parts being joined, which have been softened by means of a hot air jet in order to allow bonding to occur.

Storage tanks are formed from a wide variety of plastic materials. Of all the plastics, polyethylene is the most commonly used to fabricate storage tanks. Polyethylene, a light, chemical-resistant thermoplastic, is advantageous as a material for storage tanks because it offers high chemical inertness as well as being a very light-weight material.

55 Gallon Drums

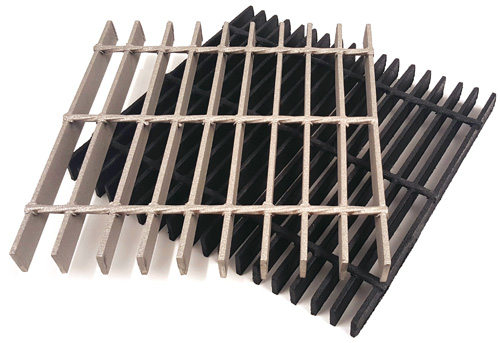

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services