INDCO, Inc.

INDCO, Inc.Request A Quote

New Albany, ININDCO is a leading manufacturer and supplier of industrial mixing equipment and accessories, based in New Albany, Indiana. The company has been in operation for over 40 years, serving customers across a wide range of industries including chemical, pharmaceutical, food and beverage, and more. Among their many offerings, INDCO specializes in designing and manufacturing high-quality plastic tanks for a variety of applications. INDCO’s plastic tanks are designed to meet the specific needs of each customer, with a range of sizes, shapes, and materials available. Their tanks are made from high-density polyethylene (HDPE) or polypropylene (PP), both of which offer excellent chemical resistance and durability. These materials are also lightweight, making them easy to handle and install. One of INDCO’s key strengths is their ability to customize tanks to fit the unique requirements of each customer. They can design and fabricate tanks in a wide range of shapes and sizes, including cylindrical, rectangular, and conical. They also offer a variety of fittings and accessories, including agitators, mixers, pumps, and valves, to meet the needs of different applications. INDCO’s plastic tanks are ideal for a wide range of applications, including chemical storage, wastewater treatment, food and beverage processing, and more. They are designed to handle corrosive and abrasive materials, as well as high temperatures and pressures. They are also easy to clean and maintain, ensuring long-lasting performance and reliability. In addition to their high-quality products, INDCO also offers a range of services to support their customers. Their experienced team of engineers and technicians can provide technical support, design assistance, and installation services to ensure that each tank is optimized for the specific needs of the customer. They also offer maintenance and repair services to keep tanks in top condition. Overall, INDCO is a trusted supplier of high-quality plastic tanks for a wide range of industrial applications. Their focus on customization and customer service sets them apart from other manufacturers in the industry, making them a top choice for businesses looking for reliable and durable tank solutions.

55 Gallon Drums

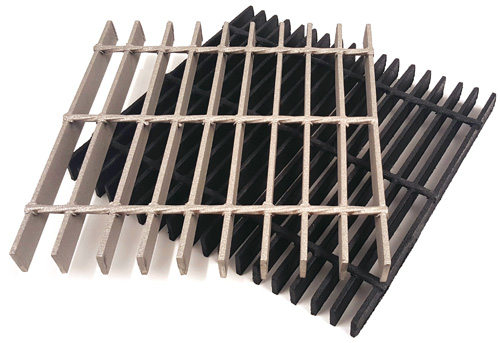

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services