Their seamless construction provides them with greater impact strength and superior resistance to rust, corrosion, chemicals, and fuel additives. These virtually indestructible tanks have a longer lifespan than steel tanks, which can fracture and leak. Read More…

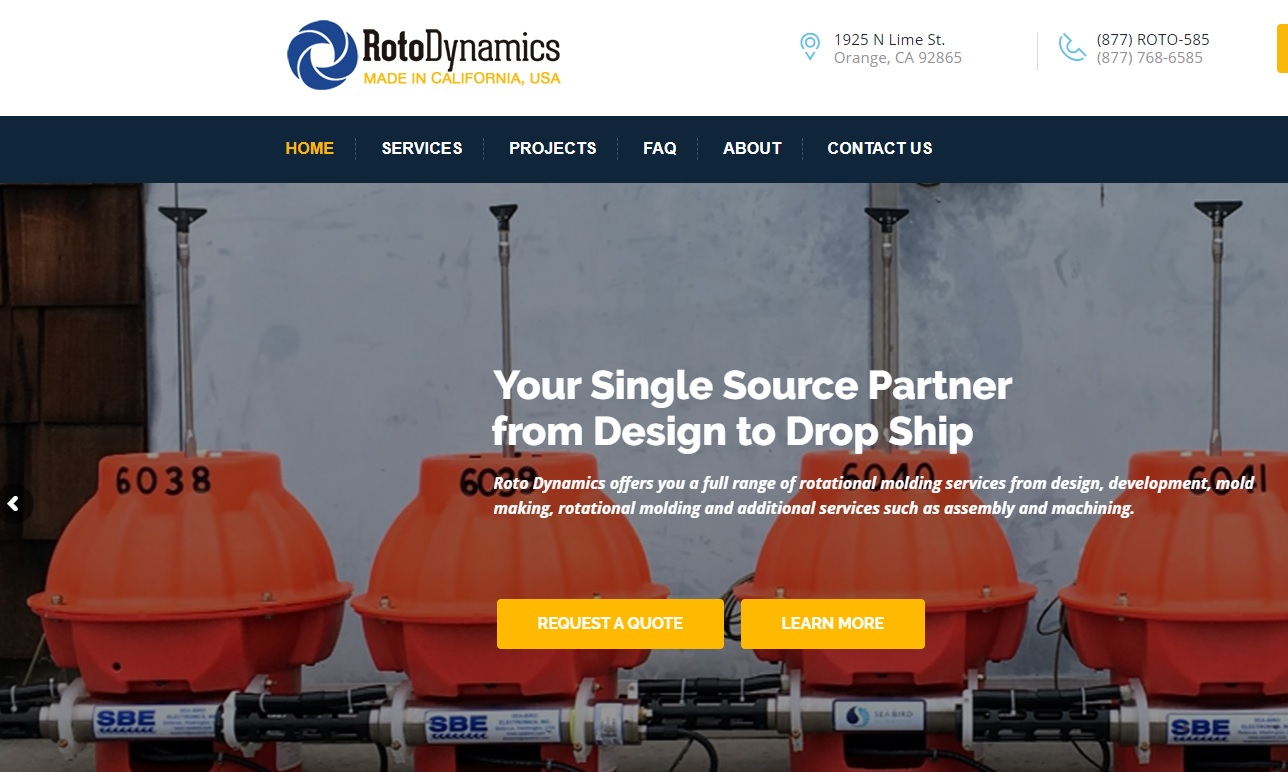

Roto Dynamics Inc., custom rotational molders serving rotomolding and plastic tank needs nationwide. We are dedicated to our customers manufacturing needs. Building customer relationships based on integrity and communication assists us in developing a competitive advantage within the industry.

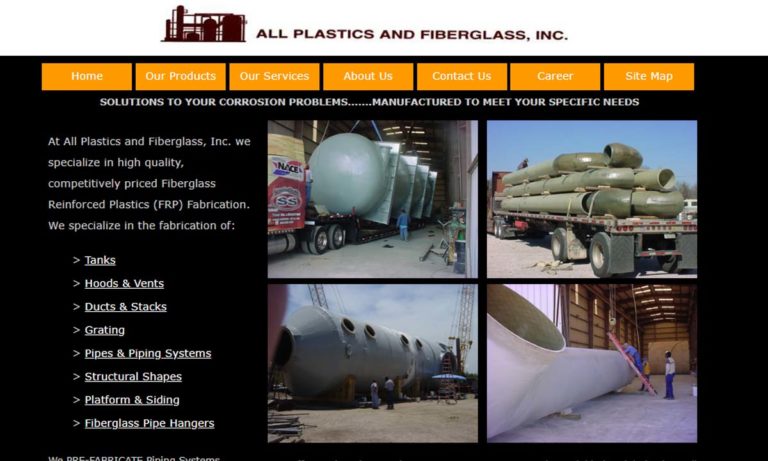

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your plastic and fiberglass needs.

Specializing in fabricated plastic tanks such as water tanks, polypropylene tanks, polyethylene tanks and storage tanks, Park Plastic Products is capable of making your plastic tank in any size or dimension.

Sherman Roto Tank specializes in tanks that are manufactured to be suitable to store and process chemicals. Our tanks are a great choice for any industry. All our products go through extensive testing in order to surpass the industry standards. We offer sizes varying from 65 gallon to 800 gallon tanks. Along with tanks we manufacture customizable stands.

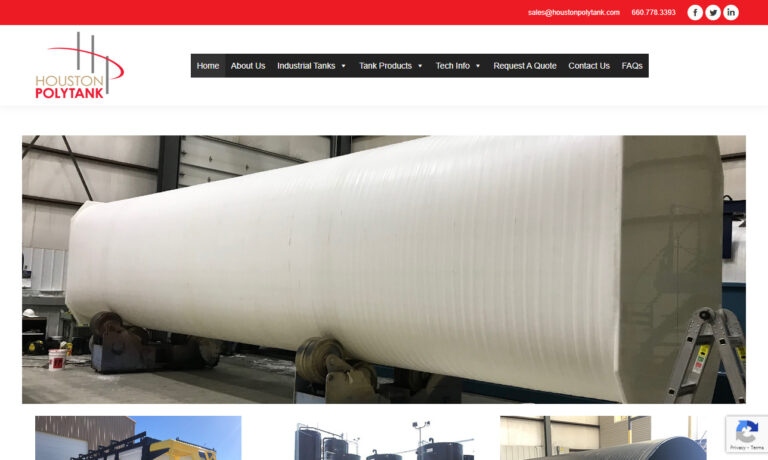

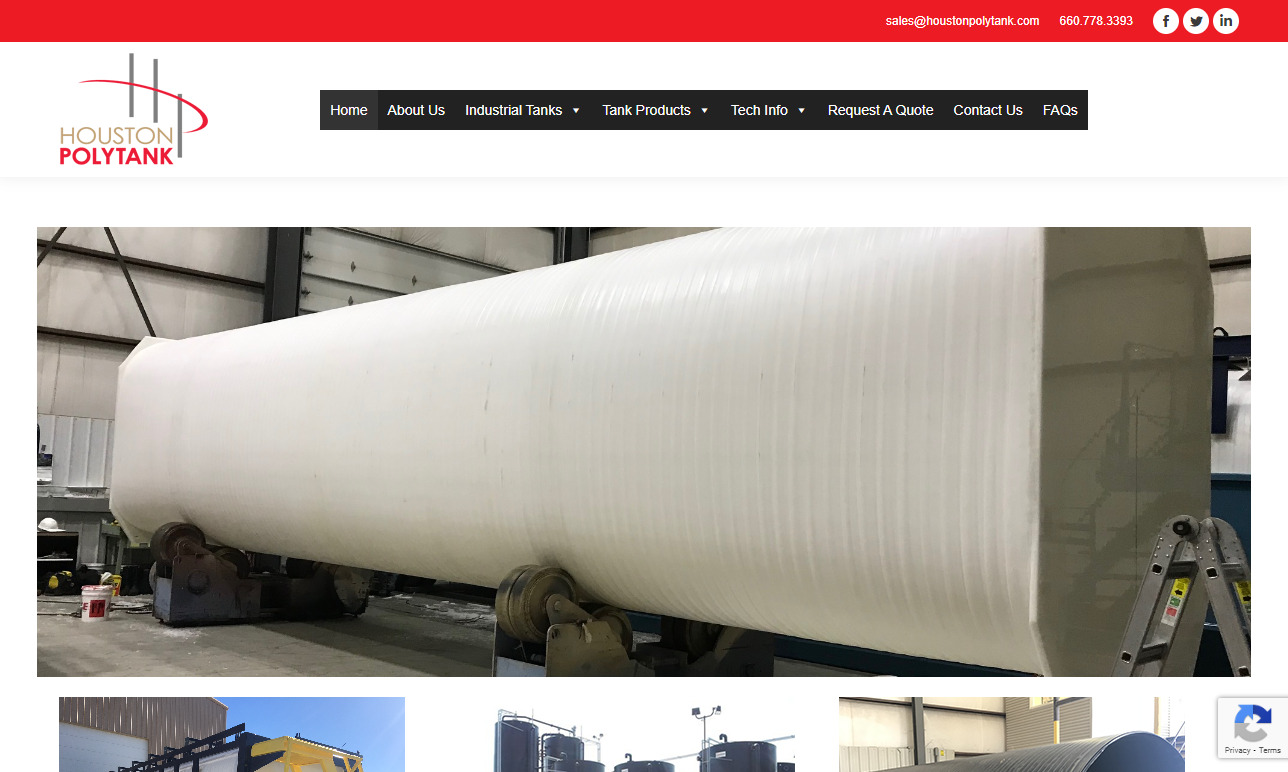

Houston PolyTank offers industrial tanks produced by wrapping bands of compressed plastic around a pre-heated mandrel, thus forming a homogeneous tank. Our cylindrical tanks store up to 50,000-gallons in capacity and our patented rectangular tanks store up to 18,000-gallons. Our industrial tanks are made of polypropylene and are heat-resistant up to 180°F. The plastic is corrosion- and...

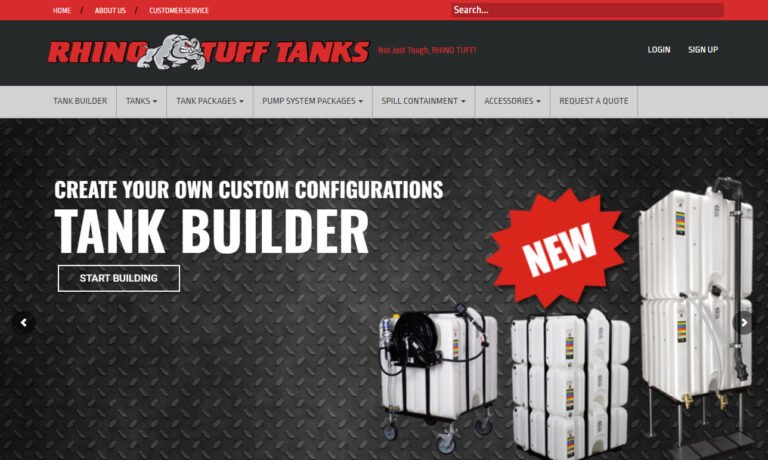

Rhino Tuff Tanks is a leading manufacturer of high density polyethylene plastic tanks. Our tanks are built to last and can easily replace 55 gallon drums and steel tanks while conserving space by stacking vertically. Rhino Tuff Tanks can be used to store fluids across a wide variety of industries, including automotive liquids, chemical fluids, farm and agricultural fluids, and industrial fluids....

More Poly Tank Manufacturers

Poly tanks can easily be molded to fit tank compartments, unlike metal tanks, and are simple to install. Poly tanks also cost less overall than steel tanks, which makes them advantageous for companies searching for less expensive storage alternatives. Poly tanks are used in a wide variety of industries and applications including: water treatment and chemical processing industries to hold such hazardous fluids as sodium hypochlorite, sulfuric acid, caustic soda, and hydrochloric acid; industrial manufacturing and processing, used in varied applications such as electroplating, recycling, parts washing and more; automotive, for use in the storage of fuels and oils such as motor oils, fuel oils and diesel fuels; and agriculture, for use in irrigation and fertilization systems for food production applications.

Some of the many types of common plastic materials used to fabricate poly tanks include polyethylene, polypropylene and polyvinyl chloride. Polyethylene (PE) is one of the many types of plastics from which poly tanks can be constructed. Polyethylene, a light, chemical-resistant thermoplastic, is the most commonly used plastic resin for storage tanks. The common types of polyethylene resins include linear high density (HDLPE), cross-linked high density (XLPE), and linear low density (LLDPE) resins.

Polypropylene (PP) is another common choice, due to its advantageous characteristics of a lightweight structure and excellent resistance to moisture and heat. Additional beneficial properties include high strength, low density and a melting point of 320º F; in fact, it is even stronger than polyethylene, though less chemically inert. Lastly, polyvinyl chloride (PVC) is another excellent material choice for poly tanks.

Polyvinyl chloride features the advantageous physical properties of being able to be combined with various additives in order to offer rigidity or flexibility; opaqueness, transparency or color; and insulating or conductivity. However, polyvinyl chloride has a negative impact on the environment and human health since it contains highly toxic elements that may leech into the ground or atmosphere. Thus, this type of plastic is less commonly used than the other two.

55 Gallon Drums

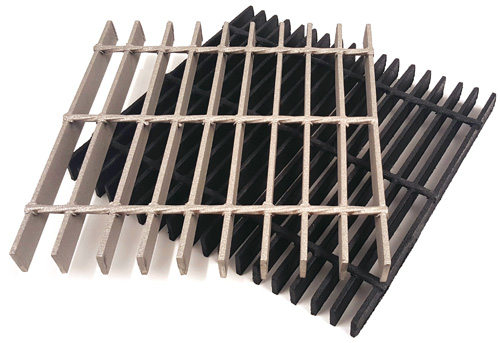

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services