Offering high reliability and superior protection against harmful chemical spills and leaks, double wall tanks protect both the worker and the environment. In addition the double walls ensure that unwanted substances will not enter and mix with the substance within the plastic tank as well. Read More…

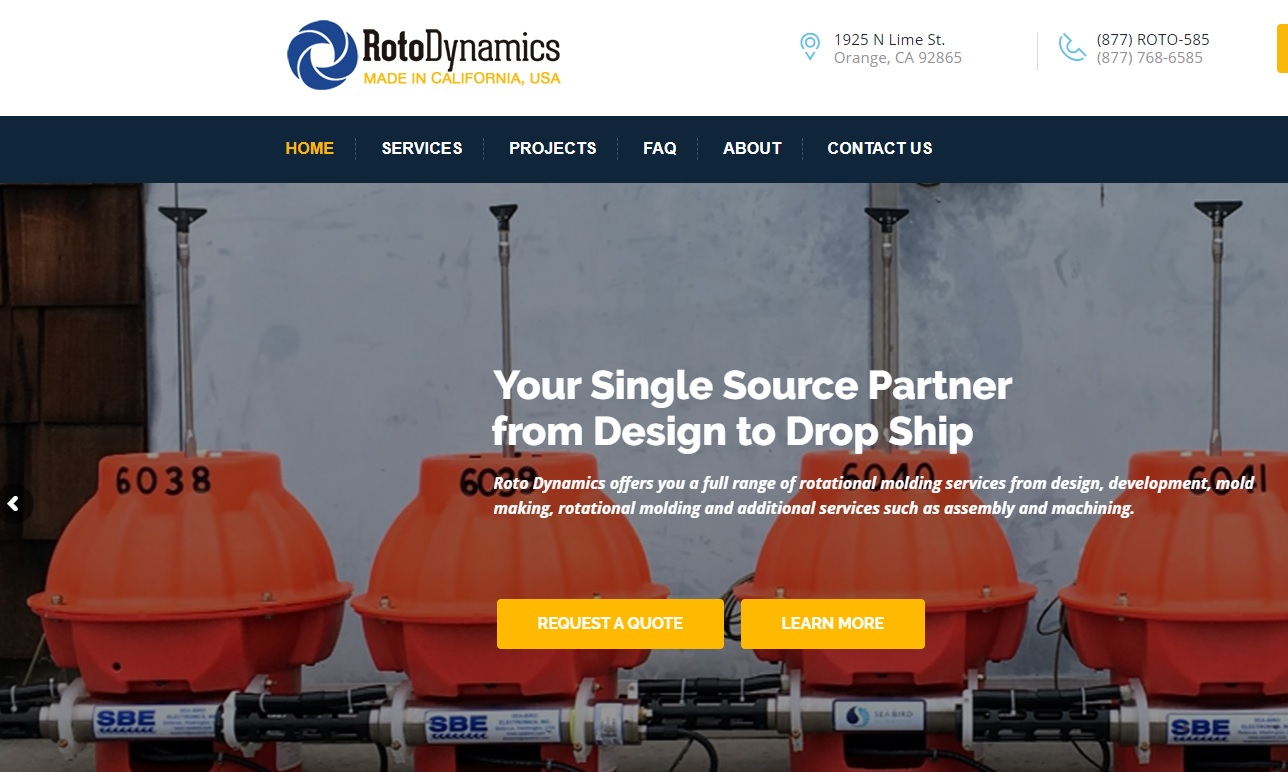

Roto Dynamics Inc., custom rotational molders serving rotomolding and plastic tank needs nationwide. We are dedicated to our customers manufacturing needs. Building customer relationships based on integrity and communication assists us in developing a competitive advantage within the industry.

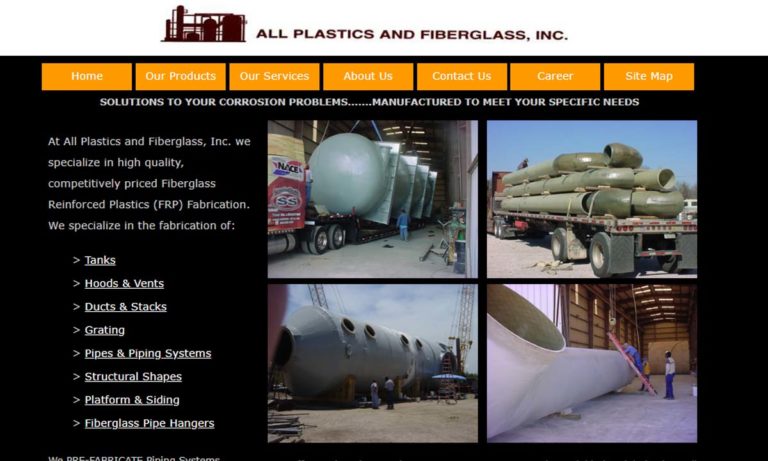

With over 100 years combined experience, All Plastics and Fiberglass has the experience to handle all your plastic and fiberglass needs.

Specializing in fabricated plastic tanks such as water tanks, polypropylene tanks, polyethylene tanks and storage tanks, Park Plastic Products is capable of making your plastic tank in any size or dimension.

Sherman Roto Tank specializes in tanks that are manufactured to be suitable to store and process chemicals. Our tanks are a great choice for any industry. All our products go through extensive testing in order to surpass the industry standards. We offer sizes varying from 65 gallon to 800 gallon tanks. Along with tanks we manufacture customizable stands.

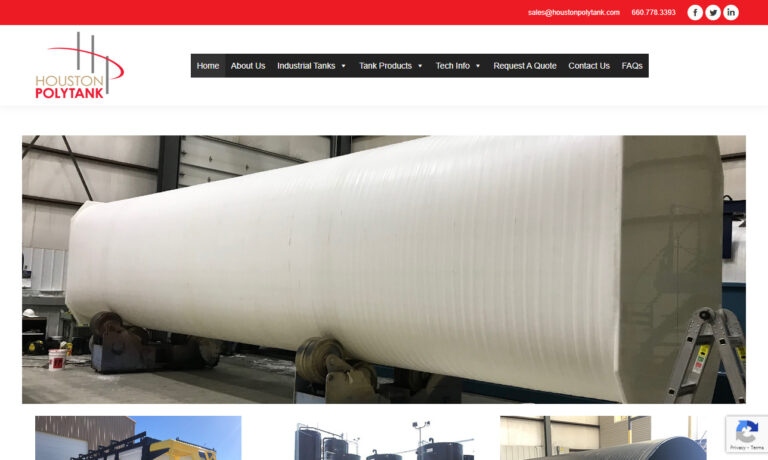

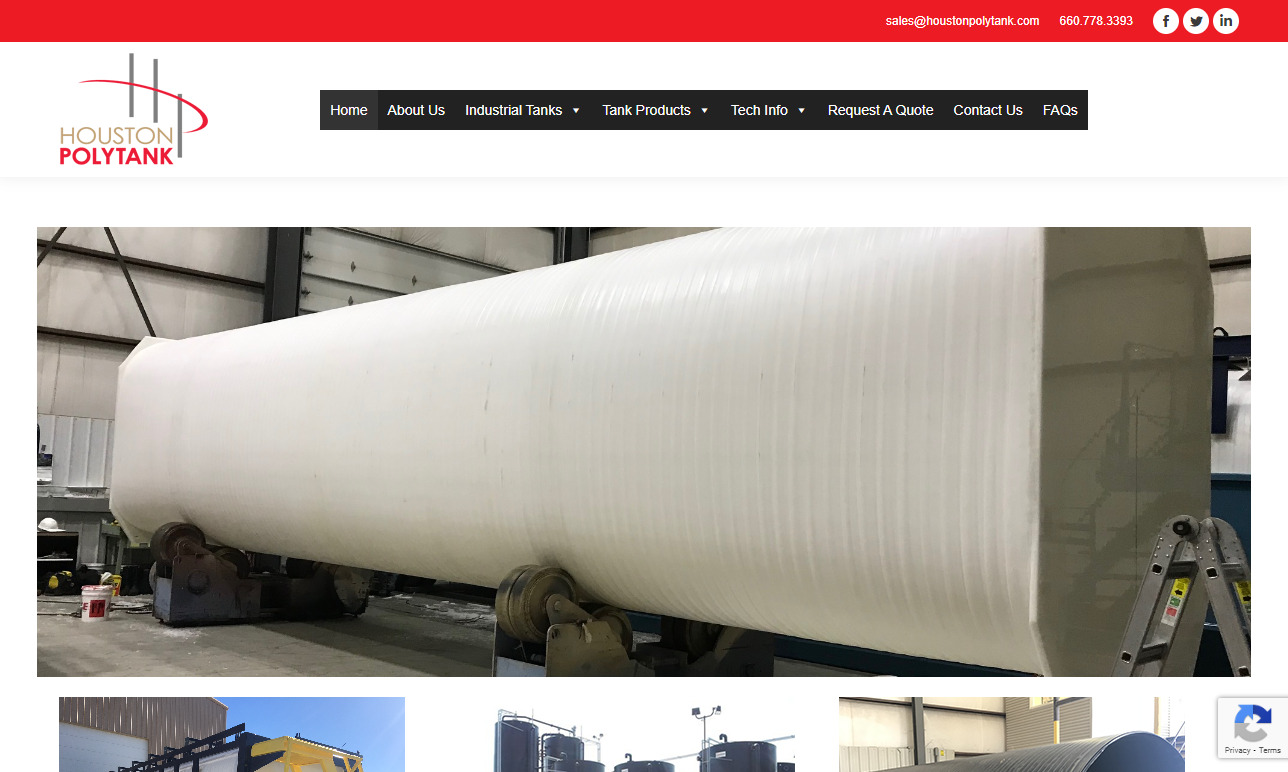

Houston PolyTank offers industrial tanks produced by wrapping bands of compressed plastic around a pre-heated mandrel, thus forming a homogeneous tank. Our cylindrical tanks store up to 50,000-gallons in capacity and our patented rectangular tanks store up to 18,000-gallons. Our industrial tanks are made of polypropylene and are heat-resistant up to 180°F. The plastic is corrosion- and...

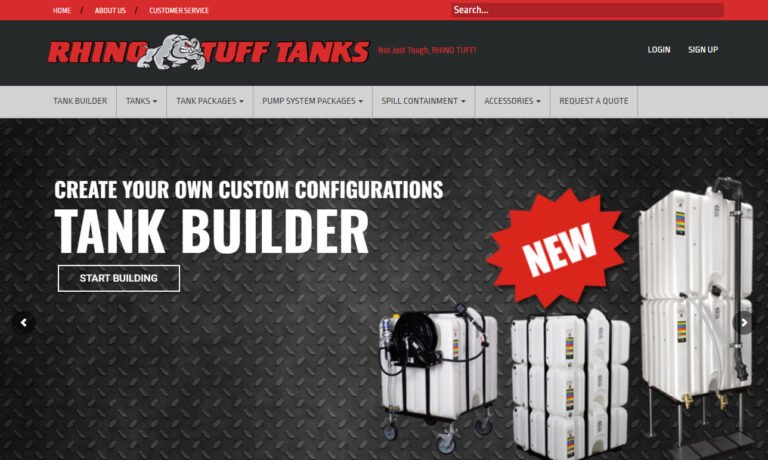

Rhino Tuff Tanks is a leading manufacturer of high density polyethylene plastic tanks. Our tanks are built to last and can easily replace 55 gallon drums and steel tanks while conserving space by stacking vertically. Rhino Tuff Tanks can be used to store fluids across a wide variety of industries, including automotive liquids, chemical fluids, farm and agricultural fluids, and industrial fluids....

More Double Wall Tank Manufacturers

Within primary production facilities, the constituent parts of a manufactured product must be brought into contact with each other somehow. While in some cases it may be cost-effective for materials to be retrieved manually by workers, in many other cases, especially in large scale manufacturing operations, mechanized materials handling equipment is much more efficient.

Assembly lines, packaging lines and other automated manufacturing processes would be impossible without conveyor systems. Pneumatic conveyor systems are widely used conveyor configurations. They can be used for the bulk handling of food, powders and many other materials in large quantities.

Beverage processing, plastics fabrication, pharmaceutical products development, watercraft and aircraft manufacturing, powder coating services, textile production, glassworking, mining and many other industries make extensive use of conveyor systems.

Air conveyors are different from mechanical conveyors, which use conveyor belts and vibrating plates to move objects. While conveyors are a good choice for some operations, air conveyors offer kinds of movement that are not possible with mechanical conveyors.

There are many different types of air conveyers. Two of those varieties are dilute phase and dense phase conveyors. Dense phase conveyors move objects with compressed air and are used for conveying mainly heavier materials such as metals and high-density plastics. As a result, these convey at a slower rate than dilute phase conveyors, which convey by diluting and suspending products with positively or negatively pressurized air.

Vacuum conveying can be used to convey smaller, lighter materials like powders and low-density plastics. Some air conveyors are named for their specific duties, such as the bulk handling conveyor, the abrasive materials conveyor and the food handling conveyor.

Air conveying is a cost-effective, reliable and quick method for transporting many different materials. Some of these materials include powders, grains, soils, sands, pills, pellets, tablets, rocks, metals, carbon black, coal, gravel, chemicals, textiles, food, plastics, wood chips, toxic waste and asbestos.

Air conveyors are highly reliable and easy to maintain, both of which features make them attractive options for many operations.

55 Gallon Drums

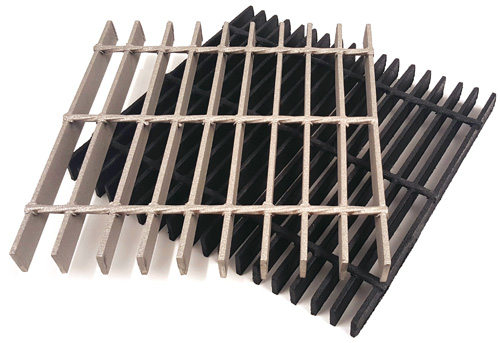

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services